RUBBER BELT MARKING, IDENTIFICATION & TRACKING

Strategic solutions for identifying and marking rubber belts.

Deliver high-quality results by prioritizing accuracy, efficiency, and image quality with experience and dedication from Computype. Boost image quality while reducing downtime and scrapped inventory with Computype’s belt marking solutions. Our belt marking solutions were developed specifically to address the challenges and goals rubber product manufacturers often face.

Rubber belt marking and labeling solutions.

- Gain practical, flexible belt printing – print-on-demand and digitally pre-printed options to suit both pre and post-cure applications

- Accomplish lean manufacturing goals – print transfer films only as they’re needed

- Vibrant color printing – in addition to barcodes, date codes, and lot numbers, print in color to enhance branding

Custom industrial identification solutions for rubber belts.

Flexible and durable rubber marking solutions engineered for industrial manufacturing environments

Our rubber marking solutions are highly flexible so your production can run efficiently, and your belt’s data and imaging remain robust and durable. We offer everything from digitally pre-printed transfer films to on-demand print systems, and everything in-between. No matter your process, data, or imaging needs we have a rubber marking solution that’s right for you.

Temperature

High-heat labeling solutions perform to 302-374 F

COLOR IMAGING

Transfer photo-realistic imagery with custom matched color

RESOLUTION

Achieve high-contrast, quality barcodes with pre-printed 800 dpi films

Print-on-demand vs pre-printed labeling solutions: how to optimize for efficiency in your plant

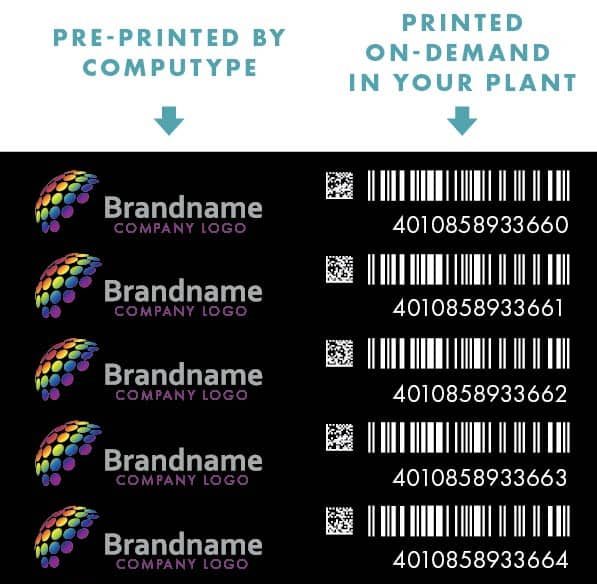

We offer three labeling strategies to help prioritize accuracy and efficiency in your plant — without sacrificing quality and flexibility. In addition to the standard blank transfer films or fully pre-printed films, we also offer a unique solution for partially pre-printed films.

What are Partially Pre-Printed Transfer Films?

Print once, apply once: reduce labor costs and streamline belt marking by adding variable data on-demand to our pre-imaged film roll. This approach combines best-in-class imaging and flexible on-demand printing to optimize efficiency in your plant.

- Achieve precision imagery and unlimited color at an affordable price with our digital printing

- Reduce material waste by combining multiple brands on the same fill roll

- Eliminate the need for pre-printed date codes by printing variable data on-demand in your plant

digitally pre-printed films

Boost efficiency, enhance image quality, reduce excess inventory

Print Technology: Digital

Print Method: Pre-Printed, Partially Pre-Printed (can request blank media for print-on-demand)

Image Resolution: 800 dpi

Film Width(s): 50 mm, 100 mm, 150 mm, custom widths

Application: Pre-cure only, post-cure application not supported

Color: Unlimited colors, including Pantone matching upon request

Quality Control: Automated barcode inspection

Print on demand blank media

Flexible belt printing to suit both pre and post-cure applications

Print Technology: Thermal Transfer

Print Method: Print-On-Demand

Image Resolution: Printer dependent

Film Width(s): 50 mm, 100 mm, 150 mm, custom widths

Application: Pre-cure only and post-cure applications supported

Color: Color available, limited opportunities compared to pre-printed digital films

Quality Control: No automated barcode inspection

Standard and custom color matching options for enhanced rubber marking

Our transfer ribbons are matched with corresponding films to improve transfer conditions and maximize image quality. A variety of colored ribbons are offered to accommodate your brand, including dual-color ribbons that allow you to differentiate information in your marking process – for example, variable barcodes on one side in white and your color brand logo on the other. If you require a colored ribbon outside of the standard range, we can offer custom shades pending development and testing.

| Color | Nearest PMS# (on rubber) | |

| Standard Red |

|

3517 C |

| Standard Orange |

|

2428 C |

| Standard Yellow |

|

102 C |

| Standard Green |

|

2242 C |

| Standard Blue |

|

299 C |

Thermal transfer printer systems for on-demand rubber marking

We have expertise in setting up printers that are optimized for your film and transfer needs. Our staff are experts at calibrating thermal transfer printers to run smoothly in any production environment. Ensuring that your printer is optimized properly can allow you to adapt quickly to changes in imaging needs, reducing inventory and labor.

Related Products and Services:

Supporting Downloads:

- Datasheet: Pre-Printed Rubber Marking Transfer Film

- Datasheet: Print on Demand Rubber Marking Transfer Film

- Case Study: Print on Demand for Rubber Belt Marking Achieves Lean Manufacturing Initiatives

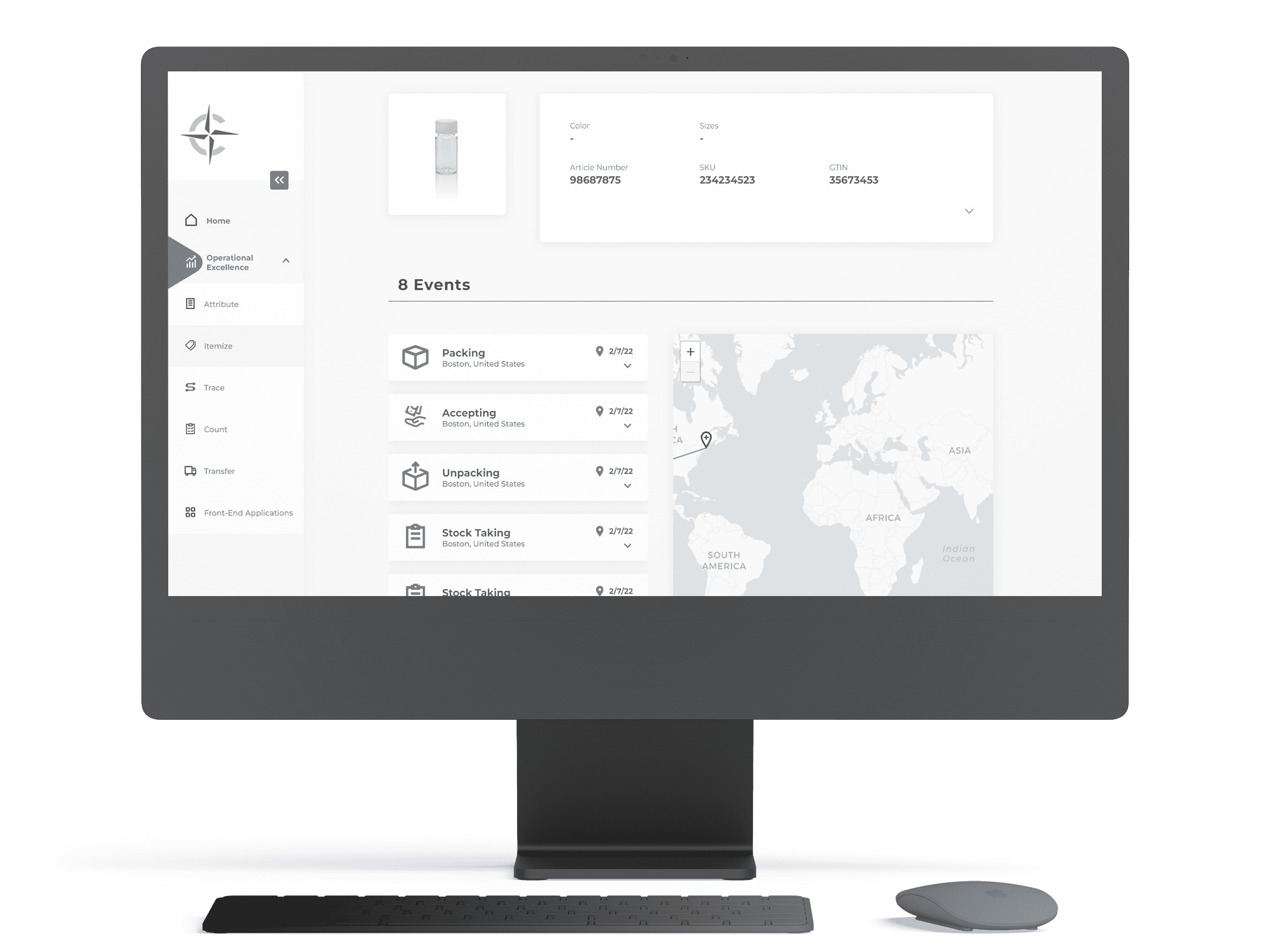

Digital Track and Trace Solutions

Tracking rubber products across multiple systems and locations can be a challenge in any manufacturing plant. Without proper infrastructures in place this can lead to higher costs and lower visibility. Computype’s Digital Traceability Platform helps track critical assets digitally and physically – monitoring storage, usage, and more.