LABWARE BARCODING & PREPARATION

Labware Prep™ Services

Receive your labware already labeled, tared, sorted, and kitted to your specifications. Experience significant time, budget, staffing, and inventory savings. Our flexible laboratory service program is the preferred choice for organizations focused on innovation and growth.

What is Labware Prep™ Services?

Labware Prep™ Services is our comprehensive program designed for laboratories. We specialize in pre-barcoding and marking labware, ensuring precision application and data accuracy.

Beyond barcoding, we handle essential prep tasks like tare-weighing, kitting, packaging, and adding custom or functional marks, such as graduated fill lines.

Our primary aim is to reduce friction in your laboratory by providing fully prepared labware and sample containers—ready for use immediately out of the box.

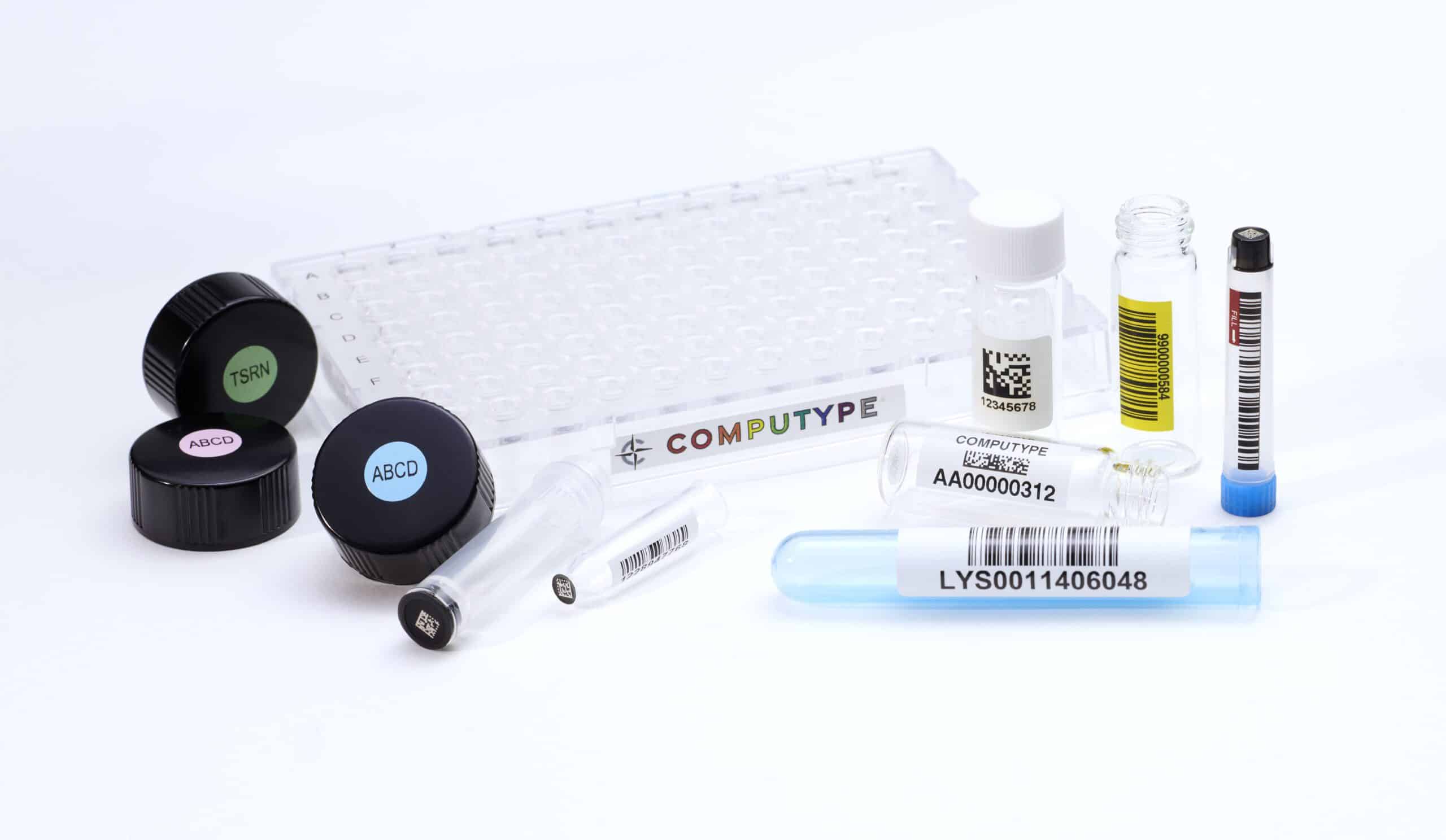

Advanced labware marking: precision, permanence, and pre-barcoding

At the core of our Labware Prep Services lies pre-barcoding, where we excel in marking technology, symbology precision, and strategic placement, ensuring unmatched labware readiness. This dedication to precision and versatility guarantees that your labware arrives not only pre-barcoded but also optimized for your exact research requirements.

- Permanent and semi-permanent barcode application

- Enhanced durability and resistance to solvents and temperature

- Custom and functional marking including grad lines

- Color and branding opportunities including custom logos

- Professional barcode label design and formatting

Tare-Weighing

Achieve precision accuracy with pre-weighed labware and comprehensive weight reports.

Nase-Controlled Production

kitting & packaging

Receive your labware assembled, sorted, and packaged to your exacting specifications.

Express Service

Ready to boost efficiency and accuracy in your lab? Let’s chat.

Labware Prep™ Services are designed to help you achieve new levels of efficiency and accuracy. Lori, our expert, is here to guide you. Schedule your free, 15-minute, no-commitment consultation today.

Explore advanced barcoding and marking

Benefit from advanced marking technologies only available through Labware Prep™ Services

Some identification solutions are simply not attainable via in-house strategies. The time, specialty equipment, and training required for advanced sample identification strategies, including ceramic bonding and cured ink direct marking, are not feasible for any laboratory to take on itself.

These technologies, however, are often required due to the extreme chemical and temperature exposures that many labs need their samples to endure—which cannot always be accomplished by standard adhesive labels. Take a look at our case study to see how our cured ink barcoding helped in one lab, or click below to explore all of our marking technologies.

Preserving trust and protecting your lab’s data and operations

In the realm of laboratory operations, trust is not simply a concept; it’s an imperative. Our Labware Prep™ Services program stands as a testament to this commitment, going above and beyond to instill confidence in every facet of laboratory management.

Protecting patient info

When tracking human samples, protecting personally identifiable (PII) information is just as important as keeping track of the sample and its history, including testing details and results. We can help assign a unique identifier to be securely associated with the PII within your LIMS—ensuring your patient’s privacy is never compromised.

risk, regulation, return

When calculating your return with Labware Prep™ Services it is important to remember all of the associated costs that come with preparing your own labware, as well as the cost of lost or damaged samples. We offer this service to support risk management just as much as we do to help with efficiency and growth.

Quality & Trust

We’ve been involved in creating new standards and innovations for identification and tracking in laboratories for nearly 50 years. Before you allow us into your processes, know that we understand the responsibility and trust required in this industry and that we uphold that steadfast commitment every step of the way.