LABELING & TRACKING SOLUTIONS FOR WAREHOUSING

Identify, track & manage warehouse inventory & locations.

Barcode labels and solutions for warehousing and logistics

- Stand-out labeling solutions for returnable transport packaging

- Various label types including pressure-sensitive, in-mold, vacuum static, and custom labels

- Support efficiency and safety throughout distribution in environmentally-friendly ways

- Flexible solutions to support pre-printed and print-on-demand strategies

- Color differentiation for at-a-glance identification

IN-MOLD TOTE LABELS

Gain permanence and supreme durability with in-mold labels

In-mold labels in the returnable transport industry are melted directly onto the tote or container during construction, meaning there is no adhesive or lining like a typical pressure-sensitive label. In-mold labels are a more permanent identification option, easily withstanding physical wear & tear and temperature & chemical exposure.

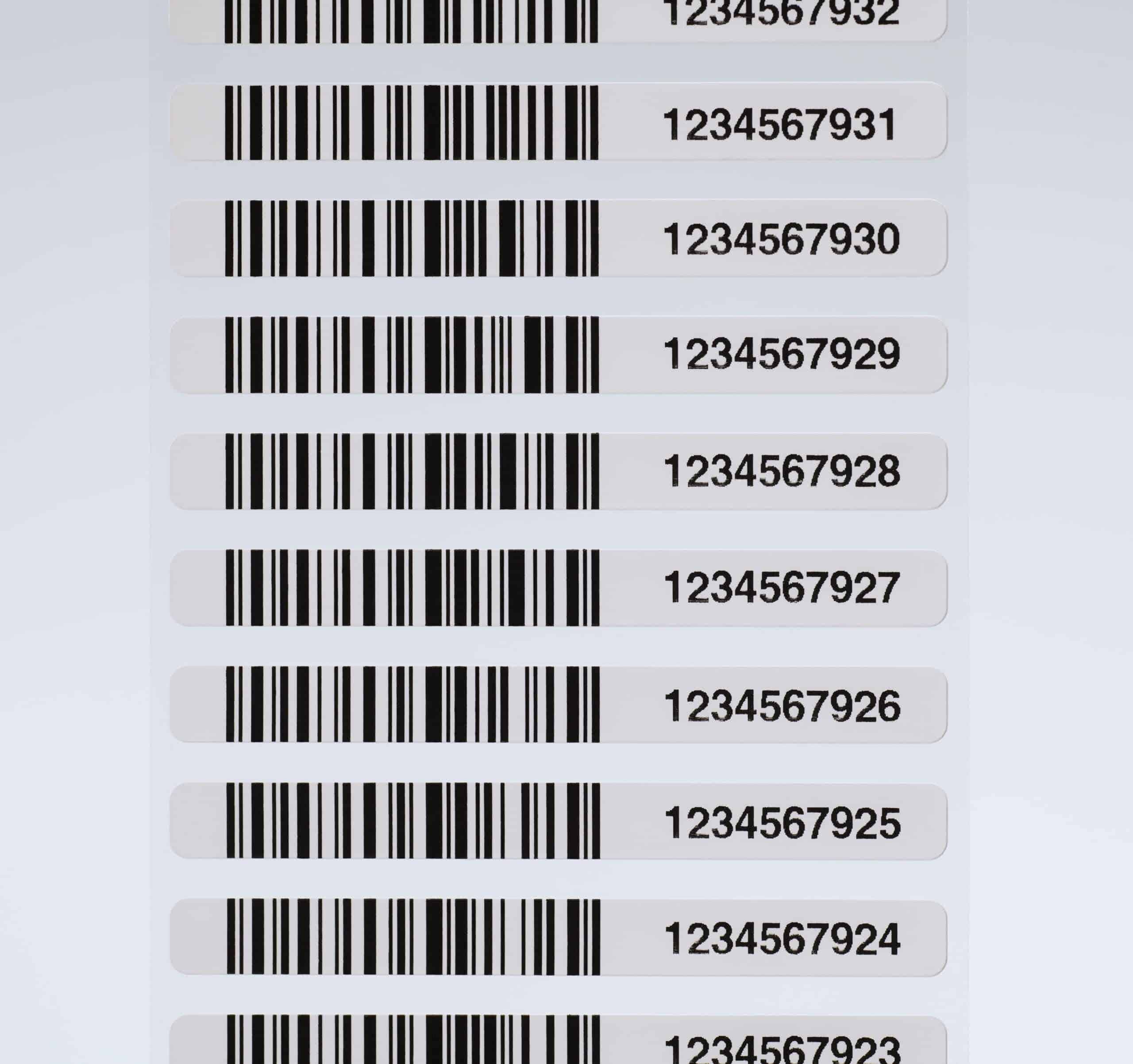

PRESSURE- SENSITIVE LABELS

Simple, flexible, reliable labels to organize your warehouse

Pressure-sensitive labels have been the most commonly utilized barcode technology, and for good reason. This barcode technology is well known, well used, and people recognize it as the standard for the identification method in the industry. Customers in this industry really like the simplicity and flexibility of pressure-sensitive labels for their totes.

Vision-based inspection system for sequence management

Every barcode on every tote will arrive at your facility having already been successfully scanned and accurately decoded thanks to our state-of-the-art vision-based inspection system.

This advanced feature in our production process scans and decodes every barcode symbol on every label set and automatically compares the decoded message to your job’s master data file.

The scan and decode process happens multiple times in succession (at production speeds of around 75 feet per minute), allowing us to verify that:

- Each decoded number is within the range of numbers requested and is not duplicated

- All symbols are in the correct position on the web

- The symbols are scannable and decoded accurately

- There is no gap in the sequence

Related Products & Resources

Supporting Articles from our blog:

- Top 6 Thermal Transfer Barcode Label Printers

- 5 Tips to Maximize the Life of Your Thermal Printhead

- Thermal Transfer vs. Direct Thermal Print Technology