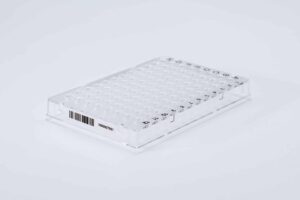

Direct mark technology offers a mid-range, semi-permanent, wildly versatile identification solution suitable for nearly any labware type. Whether it’s plastic microplates, glass vials, or conical tubes, direct mark technology can suit your entire suite of labware. Though it is deemed semi-permanent, direct mark IDs are highly durable. They will not scratch or fade when exposed to everyday laboratory tasks, including robotic handling, chemical submersion, or extreme temperature cycles.

What is Direct Mark technology?

Direct Mark is a barcoding and labeling technology that prints and cures specially formulated ink directly to the surface of your glass or plastic labware. This process creates a near-permanent mark capable of withstanding harsh chemical baths, extreme temperatures, and long-term storage.

The ability to print onto the surface of labware without a layer of media also makes it possible to include functional markings like grad-lines. Because the label information is applied directly to the surface of the labware, there is no risk of the ‘label’ peeling off. However, rough and consistent abrasion, such as filing, can remove a direct mark image.

Once again, the lack of adhesive eliminates one of the most precarious factors of a label.

Label design and barcoding with Direct Mark

Direct mark technology is highly versatile and offers the broadest range of design and formatting opportunities. Suitable for both glass and plastic labware, the customization options are nearly endless. Here are a few typical applications:

Barcodes

Barcodes rely heavily on contrast to ensure successful scanning, which is why most barcodes are black and white. Direct mark technology prints one color at a time, so we recommend printing a white background or utilizing a piece of labware that already has a white patch applied for the barcode before printing the bars with the preferred black ink.

Text

While we don’t recommend color for barcodes, text information could easily incorporate color and does not require a background patch. Any text required could maintain the transparent background of the labware.

Color Coding

Color can be a valuable tool in keeping your samples and processes organized. This method of at-a-glance identification can reduce friction and simplify tracking.

Graduated Fill Lines

Fill lines, or graduation lines, are one of our favorite use cases for direct mark technology. By adding grad lines onto the transparent background, you can increase the functionality of your tubes or vials and enhance your workflow.

Logos

Brand representation is an excellent application for direct mark technology. Including color logos on labware can promote brand awareness when sending your samples out to compound storage facilities or other customers.

Utilizing direct mark for irregular labware

Another benefit stemming from the lack of media is direct mark’s ability to adapt to unique shapes. The ink or etching can stay true to the form of irregular-shaped labware items that may be difficult to accommodate with pressure sensitive labels—like conical tubes. Additionally, direct mark has little to no effect on the diameter of the tube, making it especially suitable for applications where tubes need to be able to fit into trays.

Sourcing direct mark through pre-barcoded labware services

We offer direct mark technology through our pre-barcoded labware services offering. Direct mark technology would be highly impractical for laboratories to attempt in-house. The specialized equipment and inks required and the multi-step application process make it cumbersome for any facility not designed for this application. Our skilled operators work in a dedicated, controlled environment and utilize extensive quality control procedures. Because direct marking is so versatile, it is essential that you discuss your needs in detail when working with your labeling expert. The better we understand your workflows, testing procedures, and environment, the better solution we can design for you.

Overall, direct mark is a unique method that offers durability and adaptability to unique shapes compared to pressure sensitive labels and can include additional features like color or graduation lines. Direct mark technology provides a comfortable middle ground for laboratories that need a more robust solution than pressure-sensitive labels but don’t require the permanency of ceramic IDs.

Connect with our labelling experts today

Blog article form

"*" indicates required fields