DIGITAL TRACEABILITY PLATFORM

Cloud-based digital supply chain for tracking critical assets in life science.

Computype’s Digital Traceability Platform provides an infrastructure that allows laboratories and scientific research facilities to track critical samples and specimens digitally and physically – monitoring their environment, location, storage, usage, and more via RFID and barcode identification. Our platform is a full-service, end-to-end traceability solution that can integrate into existing systems. With this data collection, you can produce powerful intelligence and predictive analytics to inform decision-making and promote efficiency and growth.

Manage item-level laboratory data and product lifecycles with a digital supply chain.

In today’s environments, too much time is spent searching for critical assets that greatly need to be deployed. Our tracking software helps identify and monitor any supply – allowing better visibility into inventory, reduction in labor hours, and greater efficiency. Computype’s Digital Traceability Platform provides a centralized hub of information – giving you access to a single source of immutable data to inform communication and reporting.

With data collection comes data-driven results and insights. This solution for track and trace monitoring integrates into your existing systems to provide intelligence that can drive analytic decisions and process improvements.

What is digital traceability?

Digital traceability enables more robust asset tracking by assigning unique digital IDs to individual items. With these IDs, you can track, trace, monitor, and analyze assets and asset usage digitally and physically.

Regarding our Digital Traceability Platform, powered by the atma.io connected product cloud by Avery Dennison, we sought a solution we could carefully tailor to support the complex needs of our customers.

For years we’ve helped companies improve their identification and tracking with comprehensive solutions to manage assets that are key to public health, including blood samples, specimens, and potentially life-saving drugs within the B2B healthcare supply chain.

The Digital Traceability Platform creates a digital twin of your supply chain to allow you greater insight and control of your inventory and assets to support enterprise management and promote growth.

Digital Traceability Platform Solution.

Powered by the atma.io connected product cloud by Avery Dennison

The Digital Traceability Platform (DTP) enhances and enables scientific processes and the delivery of laboratory information. This solution creates an overlay connecting existing digital systems (LIMS, Warehouse Management, Enterprise Resource Planning, etc.) to provide a centralized data hub. Many laboratories must pull information from several sources when moving assets through their workflows and reporting on fundamental metrics. The Digital Traceability Platform would allow laboratory staff to access all of their information through one interface.

ENCODE DIGITAL IDS

AUTHENTICATION

MACHINE LEARNING

GLOBAL ACCESS

MANAGE WORKFLOWS

SUSTAINABILITY

Digital traceability platform modules:

Attribute

The attribute module stores product level information. You can enter new products individually or with a bulk import. Here you can edit product details, deactivate the product, and see the individual items associated with that product or SKU.

Itemize

The itemize module allows you to search for products and set the fields associated with individual products including expiration dates, minimum on hand quantities, and more.

Trace

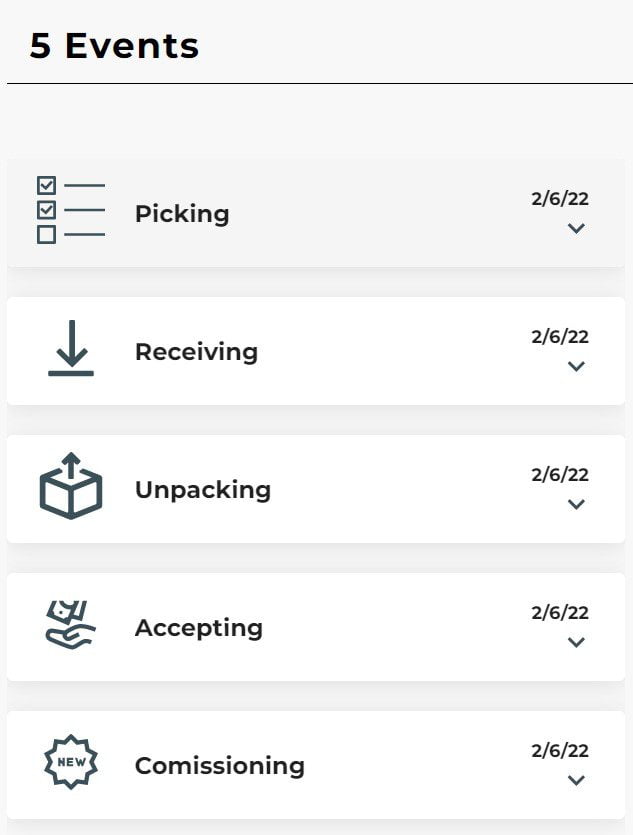

The trace module allows you to view the entire event history for a product. Each event will record details including which user initiated the event, as well as when and where the event took place.

Count

The count module provides visibility to cycle counting data, allowing you to inspect individual site inventories, and the products or SKUs found in each cycle count.

Transfer

The transfer module formalizes procedures for products moving between sites or locations. You can visualize the entire transfer process and identify any missing or surplus items.

Laboratory Data Integration and Intelligence.

Connect data from multiple systems and sources, including third-party and local data.

A less-than-robust data management strategy can lead to costly problems in any modern lab.

The Digital Traceability Platform uses artificial intelligence to provide data-driven insights into your processes. By analyzing supply chain data and applying a range of heuristic learning routines and machine learning algorithms to identify patterns and predict possible outcomes, laboratories can prevent disruptions before they happen. Any anomalies are highlighted by callouts, and actions can be taken for correction.

Furthermore, by connecting data islands and integrating them into existing systems, our platform enables consolidated reporting and analytics, which can eliminate guesswork, inform critical decisions, and help accurately prepare for future growth.

Integrate data from multiple sources including:

– Laboratory Information Management Systems (LIMS)

– Electronic Laboratory Notebooks

– Chromatography Data Systems

– Scientific Data Management Systems

– Warehouse Management Systems

– Local Files and Documents

– Enterprise Resource Planning Tools

– Business Intelligence Reporting

Identify, Track, and Monitor Samples.

Centralized master data solution for strategic laboratory planning and preparation

Our Digital Traceability Platform allows you greater insight and control of your inventory and assets to support your needs as you track, inform, and predict. These three pillars of the digital traceability platform allow for near real-time visibility of your assets and events from any location. Let’s take a deeper look at each of these pillars.

Identify and Encode

Inventory control begins by keeping accurate track of each of your assets and events. By establishing a hierarchy of those events, and making use of distributed ledger technology (DLT) to provide immutable data, you can guarantee that your assets will be properly identified and monitored.

Track and Monitor

Using customizable dashboards and visualizations, timely notifications, and aggregate reporting, you have control over your data points and information. With the Digital Traceability Platform you can do more with your data by gaining key insights that will help better manage your business.

Inform and Report

Finally, the Digital Traceability Platform will help you promote data driven improvements and identify growth opportunities by providing predictive analytics and metrics, powered by machine learning and artificial intelligence. You can predict stock out events, detect anomalies, and analyze usage rates to eliminate guesswork.

Medical Supply Chain Sustainability

Responsibly manage laboratory facilities and ensure a lean supply chain

Production Efficiency

With our Digital Traceability Platform you can use the predictive analytics and metrics to implement lean manufacturing principles and boost efficiency. A lean supply chain focuses on delivering products quickly and efficiently, leading to increased customer satisfaction.

Reduce Carbon Footprint

Over 90% of companies’ carbon emissions are created by their supply chains. Businesses must evaluate each step of their supply chain to identify new opportunities for efficiency. Our platform provides complete transparency and visibility to identify and implement improvements.

Regulatory Compliance

Data managed within Computype’s Digital Traceability Platform is immutable with hierarchies and a distributed ledger that reduces the overhead of regulatory compliance as well as helping to narrow the scope of recalls or quality issues.

Waste Reduction

Ordering mistakes, overproduction, lead times, and communication breakdowns can all lead to supply chain waste. Eliminate waste in your supply chain with immutable, centralized data from Computype’s Digital Traceability Platform.