AUTOMATED TUBE AND VIAL LABELERS

Automated vial labeling for efficient laboratory workflows.

Today, tube and vial label automation is more accessible than ever. From basic print and apply automation, to custom designed, bulk-fed label automation systems, finding an applicator to fit both your needs and your budget is simple. Here we will discuss the different levels of tube label automation and the applicators available at each level.

Incorporating labeling into your automated workflows.

Introducing label automation to lab automation marks a significant advancement in streamlining laboratory workflows.

Automated vial labelers offer a game-changing solution, saving valuable time and enhancing accuracy in labeling processes.

By seamlessly integrating automatic vial labelers into lab operations, you can optimize sample tracking, minimize human error, and ensure compliance with regulatory requirements.

These systems revolutionize efficiency and data integrity, making them invaluable to any laboratory environment.

What level of automation do you need in your lab?

Label automation comes in multiple different levels—from basic print and apply to complex, robust, highly engineered machines. One key factor to differentiate these levels is the amount of operator involvement required. Learn more about levels of automation in the lab.

Manually Operated Labelers

Many print-and-apply vial labelers require operator involvement to present each tube, initiate the labeling sequence, and swap out the next tube. This option offers an easy upgrade for laboratories that just need to reduce some of the errors and stress resulting from their current manual application processes.

Bulk Fed Labeling Systems

Some vial labeling systems may include a bulk feed option—allowing you to initiate a large batch of labeling to process without anyone present, potentially overnight. This could also be achieved by utilizing pick-and-place robotic handling to keep your tubes and vials moving through your workflow.

Custom Engineering

In unique cases where extremely high processing speeds are required, you could consider commissioning a custom-engineered labeling system. Take a look at one of our recent projects to get a better sense of what is possible with custom engineering.

Explore select tube and vial labelers

Elevate your labeling game with our cutting-edge selection of tube and vial labelers. These precision instruments are designed to enhance accuracy, streamline processes, and boost efficiency in your lab operations. Discover the perfect labeling solution to revolutionize your workflow.

CAB AXON 2

Semi-automated print and apply labeling

The Axon 2 print and apply desktop solution is reliable, affordable, and an ideal first step for laboratories considering automation.

- 300 and 600 dpi print resolution

- 1D and 2D barcode encoding

- Print apply within 2 seconds per tube

- Label width up to 110 mm

- Tube diameter between 10 and 22 mm

- Horizontal tube orientation

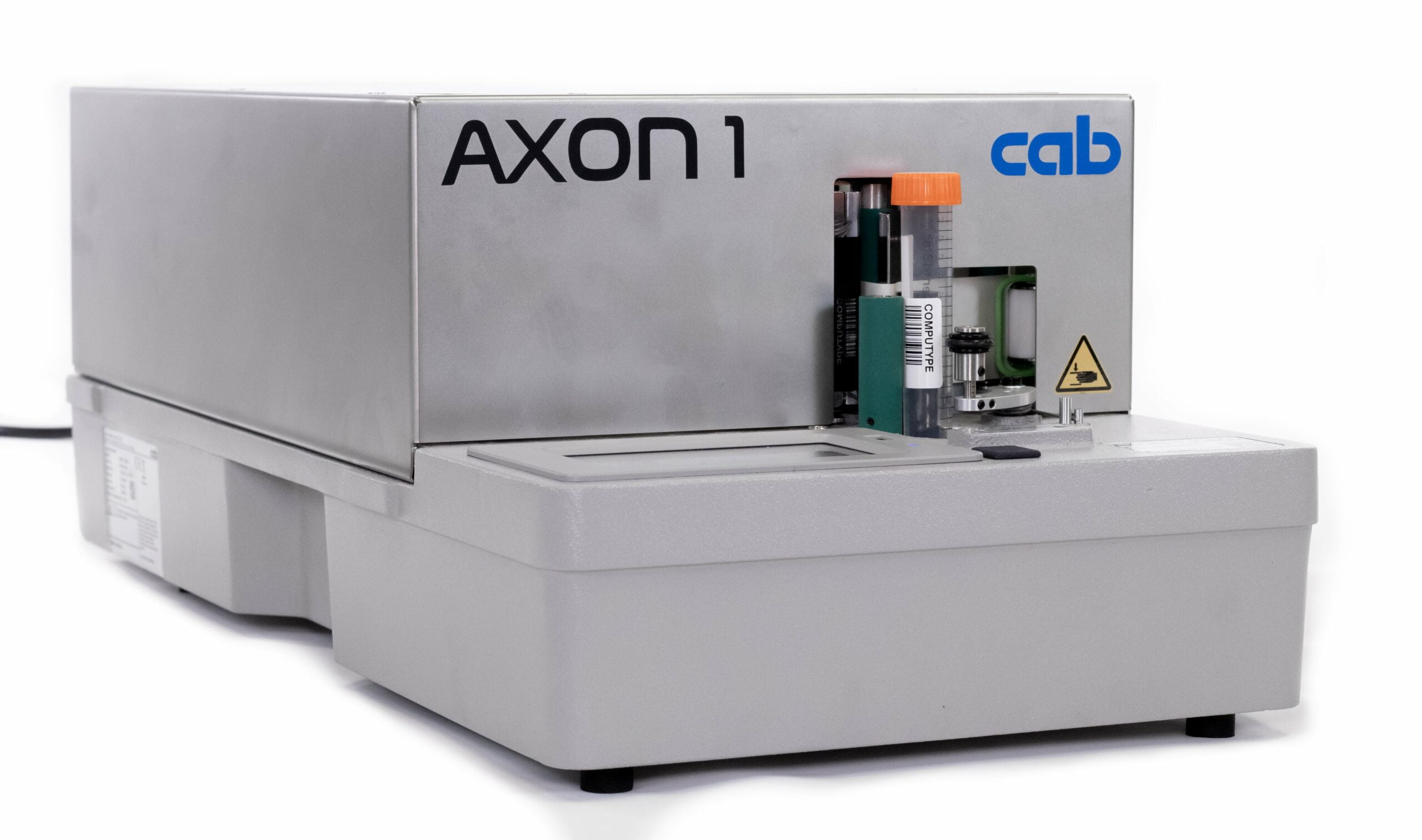

CAB AXON 1

Scalable automation fit for robotic handling

The cab Axon 1 automated print-applicator can operate as a standalone system or integrate with large-scale laboratory automation.

- 300 and 600 dpi print resolution

- 1D and 2D barcode encoding

- Print and apply within 2 seconds per tube

- Label width up to 56 mm

- Tube diameter between 7 and 26 mm

- Vertical tube orientation

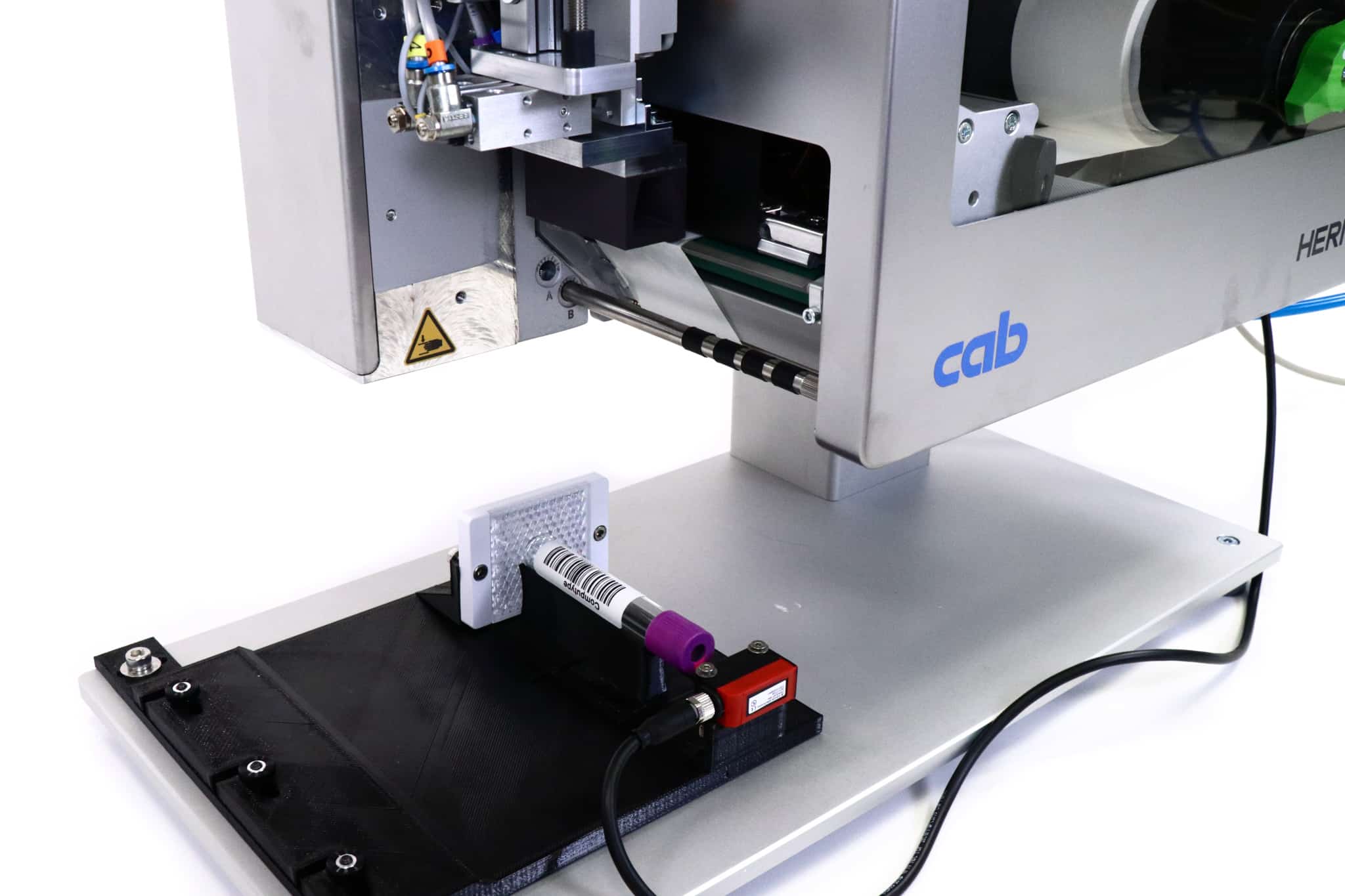

CAB HERMES Q

Specialty applicator for larger bottles

The cab Hermes Q brings industrial strength automation to your laboratory to accommodate reagent bottles and other large cylindrical containers.

- 300 and 600 dpi print resolution

- 1D and 2D barcode encoding

- Label width up to 110 mm

- Custom tube diameter

- Horizontal tube orientation

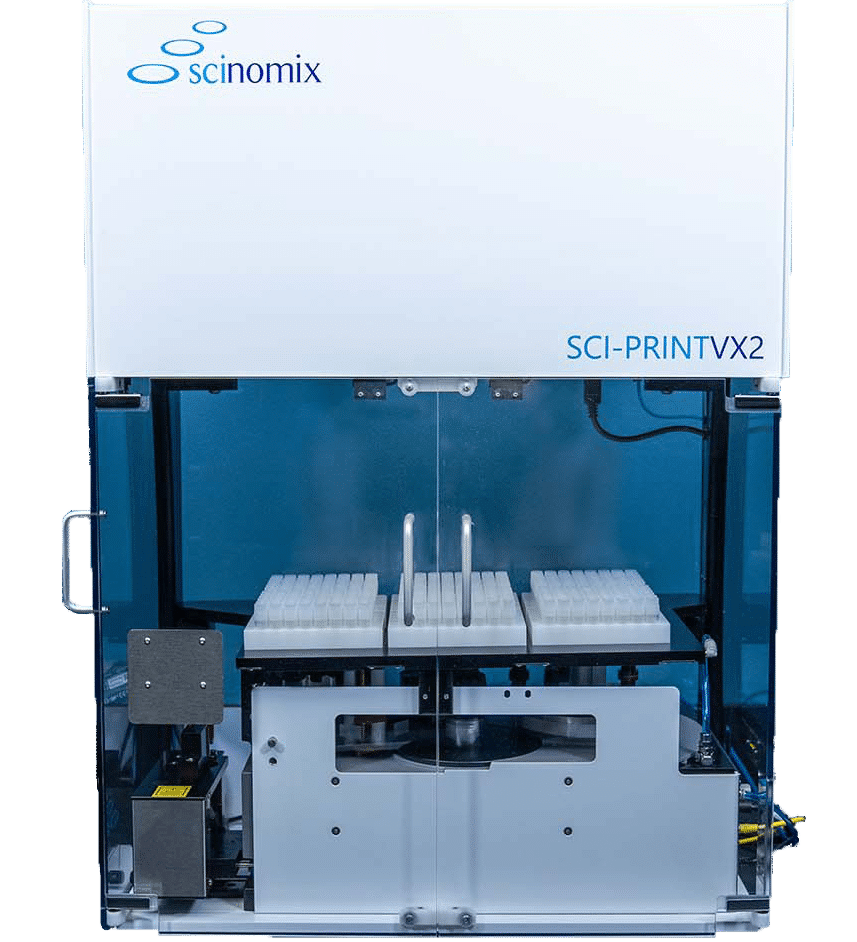

SCINOMIX SCI-PRINT VX2

Bulk-fed tube labeling for walkaway automation

High-volume, large-scale needs are easily met by Scinomix solutions. This walkaway solution can receive bulk tubes, sort racked tubes, as well as uncap and recap tubes.

- Process up to 375 tubes/hour

- 2D scanner

- Tube volume from 0.5 mL to 50 mL

- Vertical tube orientation

- Filling, uncapping, and recapping

Take a look at how we utilize label automation in our own facility

We have collaborated multiple times with PaR Systems, a highly skilled intelligent solutions provider well known for their work in robotic automation systems.

Together we have provided advanced solutions for our customers in their facilities, as well as in our own facility.

We ulitize this fully automated work cell to prepare labware for our customers in-house, allowing them to focus their time and effort on their important research goals, instead of tediuous prep tasks.