MICROPLATE LABELS

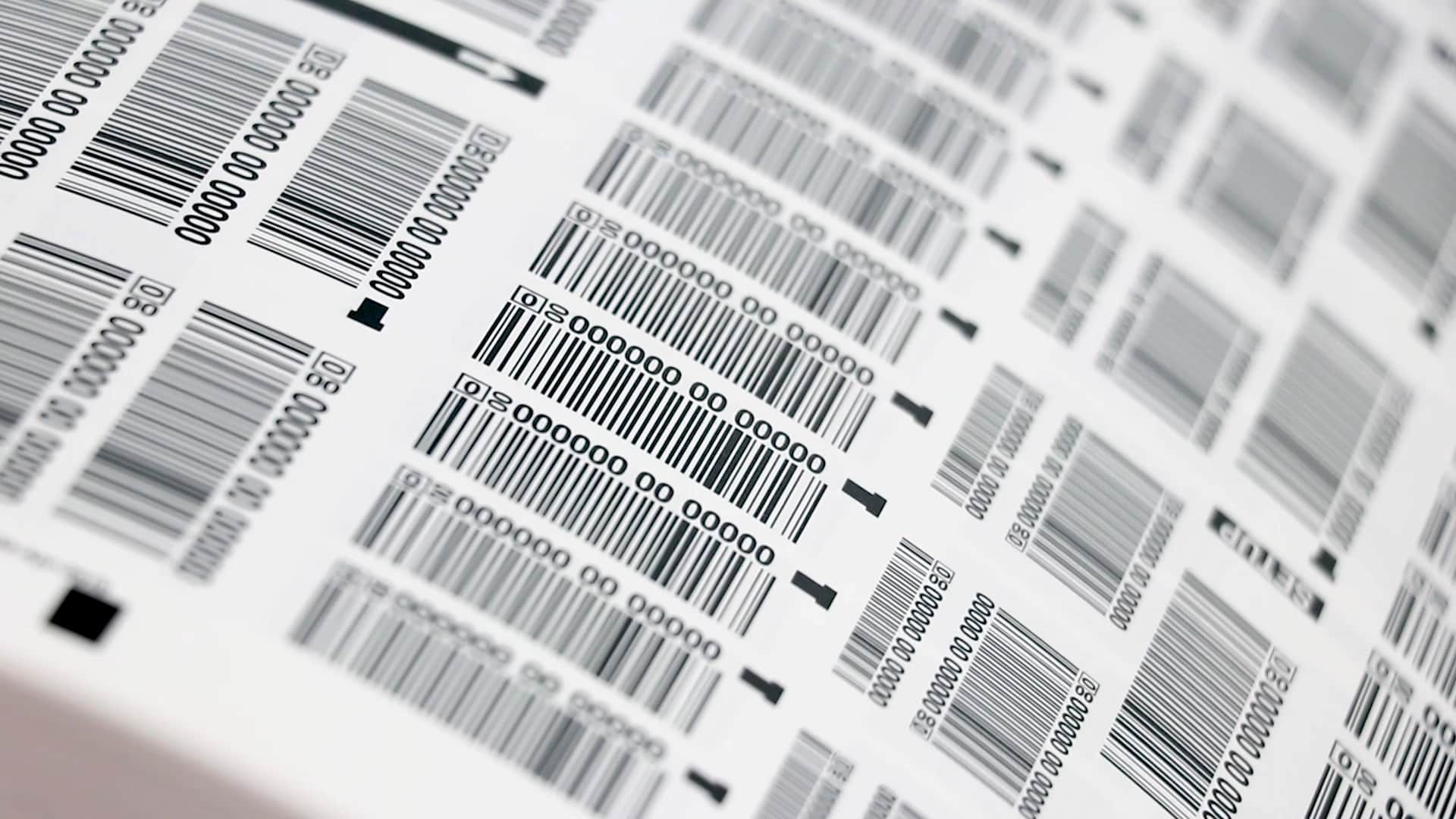

Barcode labels and tracking solutions for every microplate.

Improve efficiency and accuracy in biopharma research and high-throughput screening with the right identification and tracking strategy. Our precision barcodes printed on durable label materials align with the height restraints of standard SBS-plates means accurate identification and traceability of every well. Combined with efficiency and process-improving innovations like RFID and automation, you’ll be reducing expense, labor & errors in no time.

Experience superior results with purpose-built microplate labels

Standard and custom sizes available to accommodate every need, including low-profile plates

Save time and eliminate rework with dependable labels that remain readable and affixed through analytic procedures, to enable skilled personnel to concentrate on scientific activities

Add flexibility and choose from print-on-demand, pre-printed, automatic application, and more tailored solutions to suit your process and budget

Durably engineered barcode labels for microplates

Easily identify a wide range of well plate sizes, including deep well plates, half-skirt plates, standard SBS plates, and more with our comprehensive labeling solutions. Elevate your workflow management with our advanced RFID and tracking software, ensuring efficient well-mapping and organization.

| Standard Tube Labels | Specifics | Benefit |

| Sizes | Standard sizes include 2.5″ x .25″, 2″ x .25″, and more | Custom sizes plus a general range of standard sizes based on common plates |

| Materials | Polypropylene preferred | Material selection based on required resistance to chemicals, temperatures, and abrasion |

| Adhesives | Permanent adhesive, FDA 21 CFR 175.105 certified | Custom engineered adhesives to suit different temperatures and applications |

| Printing | Blank or pre-printed | Choose blank or pre-printed labels, or ask us about partially pre-printed labels |

| Color | CMYK | Improve at-a-glance identification with color-coded label elements |

Strategic solutions to enhance tracking and automation in plate-based assays

From high-throughput screening and sample storage to cell-based assays and ELISA, assay plates are essential in various applications. Our commitment is to provide identification and tracking solutions tailored to your unique needs, ensuring that your lab’s requirements are met, no matter the complexity of your microplate usage. We’re here to support your diverse use cases and help you achieve optimal results.

Automated Plate Labeler

Boost accuracy and efficiency with compact, reliable automated plate labelers—including this print-and-apply solution from cab Technologies based on their state-of-the-art SQUIX printer.

These cutting-edge systems are engineered to deliver precision label placement at high speeds—significantly increasing throughput while reducing errors and rework.

LabTrack™ Software

Elevate your operations with LabTrack™ for comprehensive microplate tracking. Gain complete end-to-end traceability, eliminating blind spots and ensuring a seamless chain of custody.

LabTrack™ offers complete visibility, streamlining sample management, reducing errors, and ensuring regulatory compliance.

Barcode expertise: precision formatting and design

Unique sample identification is the lifeblood of every data-driven lab. In your lab, every sample, every test, every data point matters. We understand the vital role of unique identifiers in your lab’s success, offering tailored solutions for error-free tracking and reliable scans.

- High-contrast barcodes for reliable scans

- Linear and 2D symbologies to match any application

- Manual and digital sequence quality checks

- Ensure compatibility with software and instruments

- Facilitate accurate, reliable data capture

- Enhance automated workflows and dynamic routing

Related Products and Services:

- Labware Prep™ Services

- cab SQUIX Automated Microplate Labeler

- Eclipse Automated Plate Labeling System

- Cryogenic Labels

Supporting Resources:

Lab applications for tubes and vials.

High-Throughput Screening

Support plate-based assays and automation with engineered barcode solutions.

Sample Inventories

Easily manage sample inventories from small labs to global banks and repositories.

PCR & DNA

Discover non-adhesive data matrix barcodes for PCR plates, racks, connected strips, and more.