VULCANIZED RUBBER AIR SPRING SUSPENSION LABELS

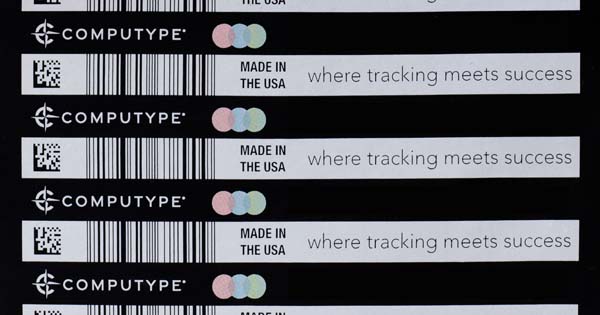

Industrial vulcanized barcode labels for rubber air spring bellows.

Ensure lifetime traceability of your parts with our preferred barcode labels for vulcanized rubber. Our experience and expertise identifying tire and rubber products enabled us to provide this additional solution for air springs and automotive parts. Encode, track, and store greater amounts of variable data with these custom data matrix codes.

Barcode labels and solutions for vulcanized rubber.

- Support WIP tracking – applying barcodes pre-cure helps maintain a better audit trail and gain control over your process

- Preserve data through vulcanization – the barcode label remains adhered and scannable through even the harshest of vulcanization processes

- Minimize and streamline product recalls – increased tracking can allow faster troubleshooting and recall responses

- Never lose sight of your data – store greater amounts of variable data in a digital format

Custom data matrix labels engineered to preserve data throughout vulcanization

Thousands of parts comprise an automobile, and all of them are crucial to the performance and safety of the vehicle. Computype never loses sight of this fact; our solutions enable the efficient and accurate traceability of every component. We have provided pre-cure barcode labels to the tire industry for over 30 years. We’ve tested and improved our solution to ensure these labels remain affixed and scannable through any procedure, including vulcanization, so you never lose your data. Now, we’ve expanded our portfolio to support additional automotive parts with our air spring labels.

Air Spring Labels

Symbology: Data matrix codes allow for greater data storage capacity compared to linear barcodes

Placement: Labels adhere directly to pre-cure rubber, extending traceability and allowing you to track the rubber bellows independently from the bead plate

Durability: Label materials survive vulcanization and abrasion—remaining securely affixed through extreme quality testing

Put your labels to the test. Check out this scratch test demo to see how one of our custom engineered labels can survive vulcanization.

Computype quality means every constituent of your labeling system is optimized for performance, so accurate tracking becomes much more dependable. We’ve built our knowledge in the rubber industry for more than 30 years, particularly working with tires. Watch this video to see our globally trusted tire labels put to the test to gain a better understanding of our experience.

Additional identification and tracking solutions for rubber products

TIRE BEAD LABELS

Robust, high-contrast tire barcode labels for pre-cure application

Trusted by some of the largest global tire makers, our vulcanized tire labels can be fully leveraged partially pre-printed or fully printed-on-demand, and are tough enough to withstand vulcanization and abrasion.

RUBBER BELT MARKING

Digitally pre-printed color transfer films for marking rubber belts

Our rubber marking solutions are highly flexible so your production can run efficiently, and your product’s integrity remains intact. No matter your process, data, or imaging needs we have a rubber marking solution that’s right for you.

Related Products and Services:

Related Articles from our blog:

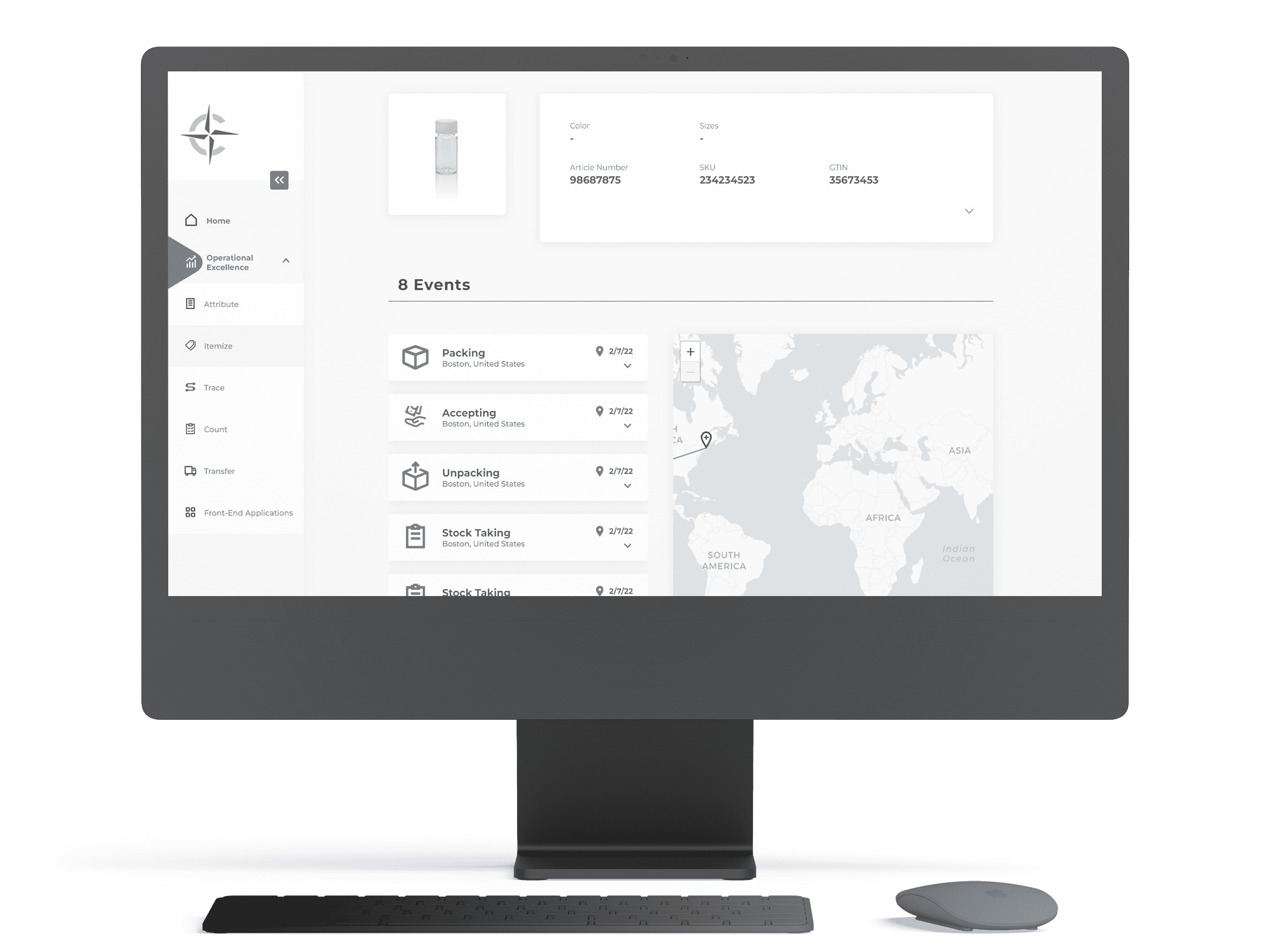

Digital Track and Trace Solutions

Tracking tires, belts, or automotive parts across multiple systems and locations can be a challenge in any manufacturing plant. Without proper infrastructures in place this can lead to higher costs and lower visibility. Computype’s Digital Traceability Platform helps track critical assets digitally and physically – monitoring storage, usage, and more.