In the world of chemicals and hazardous materials, safety is paramount. Ensuring that these substances are handled, transported, and used safely is essential for protecting both human health and the environment. One crucial aspect of this safety regime is the Globally Harmonized System of Classification and Labeling of Chemicals, commonly known as GHS labeling. In this comprehensive guide, we’ll delve into what GHS labeling is, its origins, who needs to use it, and how to ensure compliance.

What is GHS Labeling?

GHS labeling is a standardized system for classifying and labeling chemicals and hazardous substances. It provides a globally harmonized approach to identifying chemical hazards and communicating those hazards through labels and safety data sheets (SDS). The primary goal of GHS labeling is to enhance the protection of human health and the environment by ensuring that relevant information about chemical safety is communicated effectively.

Origins of GHS

The roots of GHS labeling can be traced back to the early 1990s when various countries and international organizations recognized the need for a standardized system for classifying and labeling chemicals. The United Nations took the lead in developing such a system, which culminated in the adoption of the first edition of the GHS in 2003.

Since then, the GHS has undergone several revisions to refine and improve its effectiveness. The most recent version, Revision 7, was published in 2017. Today, GHS is widely adopted by countries around the world, providing a common framework for chemical hazard communication.

Who needs to use GHS labeling?

GHS labeling is relevant to a wide range of stakeholders involved in the production, distribution, and use of chemicals. This includes:

Chemical Manufacturers: Companies that produce chemicals must classify their products according to the GHS criteria and provide appropriate labels and SDSs to downstream users.

Distributors: Entities involved in the distribution of chemicals must ensure that products are properly labeled and accompanied by SDSs as required by the GHS.

Employers: Employers who use chemicals in their workplaces are responsible for ensuring that their employees are trained on the hazards of these substances and understand how to interpret GHS labels and SDSs.

Transportation and Logistics: Organizations involved in the transportation of hazardous chemicals must comply with GHS labeling requirements to ensure that these substances are handled safely during transit.

Benefits of GHS Labeling

Adopting GHS labeling offers several benefits for all stakeholders involved:

Improved Safety: By providing standardized information about chemical hazards, GHS labeling helps to enhance safety in workplaces and communities, reducing the risk of accidents and exposures.

Global Harmonization: GHS labeling facilitates international trade by harmonizing the classification and communication of chemical hazards, making it easier for companies to comply with regulations in multiple jurisdictions.

Increased Awareness: GHS labels raise awareness about the hazards of chemicals among workers, emergency responders, and the general public, empowering them to take appropriate precautions when handling or encountering these substances.

Environmental Protection: By promoting safer handling and disposal practices, GHS labeling contributes to the protection of the environment from the adverse effects of hazardous chemicals.

6 components of a GHS label.

A GHS label contains several key components designed to convey essential information about the hazards of a chemical substance. These components are standardized to ensure consistency and clarity across different products and jurisdictions. Here are the 6 required elements on a GHS label:

Product Identifier

This is the name or code that uniquely identifies the chemical or hazardous substance. It could be the chemical name, a trade name, or a product code assigned by the manufacturer.

Signal Word

The signal word indicates the severity of the hazard and serves as a quick indicator of the level of risk associated with the substance. There are two signal words used in GHS labeling:

Danger: Used for more severe hazards, indicating a high level of risk.

Warning: Used for less severe hazards, indicating a moderate level of risk.

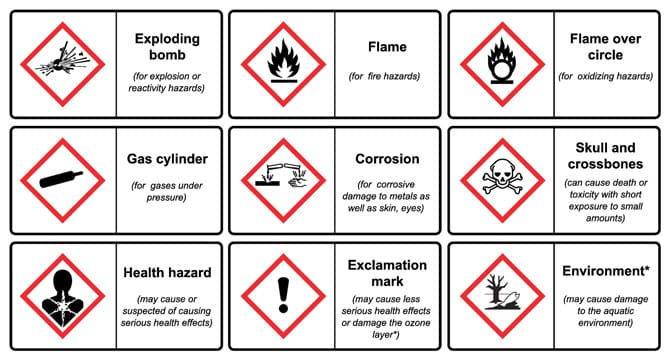

Hazard Pictograms

These are graphical symbols used to represent specific types of hazards associated with the chemical. Each pictogram has a unique shape and color, making it easily identifiable. There are a total of nine GHS pictograms, each corresponding to a different hazard category. Some common pictograms include:

- Flame

- Health Hazard

- Exclamation Mark

- Skull and Crossbones

Hazard Statements

These are standardized phrases that describe the nature and degree of the hazards posed by the chemical. Hazard statements provide more detailed information about the specific risks associated with the substance. For example, “May cause respiratory irritation” or “Highly flammable liquid and vapor.”

Precautionary Statements

These statements provide guidance on how to safely handle, store, and dispose of the chemical to minimize the risks associated with its use. Precautionary statements cover topics such as personal protective equipment (PPE), storage conditions, and emergency response procedures. For instance, “Wear protective gloves/eye protection/face protection” or “Keep away from heat/sparks/open flames/hot surfaces.”

Supplier Information

This includes the name, address, and contact information of the manufacturer, importer, or supplier responsible for the product. This information helps users to identify the source of the chemical and contact the supplier if necessary.

Depending on the specific regulations or requirements of a particular jurisdiction, GHS labels may also include additional information such as batch numbers, production dates, or specific handling instructions. By including these standardized components on GHS labels, manufacturers and suppliers can effectively communicate the hazards of chemical substances to users, enabling them to handle and use these products safely and appropriately.

Approved pictograms.

Pictograms must be combined with the corresponding elements of a GHS label. Critical information is communicated quickly and effectively via the OSHA-approved pictograms shown in the table below.

| Pictogram | Name | Hazard Details |

|

Health Hazard | Germ Cell Mutagenicity; Carcinogenicity; Organ Damage; Birth Defects; Aspiration Hazard; Breathing Difficulties, Allergies, or Asthma if inhaled |

|

Flame | Oxidizer, may intensify fire; Oxidizing gas; Flammable gas; Aerosol; Flammable Liquid; Flammable Solid; Heating may cause fire |

|

Exclamation Mark | Harmful if swallowed; Toxic if inhaled; Harmful if in contact with skin; May cause an allergic skin reaction; May cause respiratory irritation |

|

Gas Cylinder | Gas under pressure |

|

Corrosion | Corrosive to metals; Causes serious eye damage |

|

Exploding Bomb | Explosive; Heating may cause fire or explosion |

|

Flame over Circle | In contact with water, releases flammable gas; Self-reactive substance/mixture; Self-heating; Catches fire spontaneously if exposed to air |

|

Skull and Crossbones | Acute toxicity oral; Acute toxicity skin; Causes serious eye irritation |

|

Environment | Aquatic environmental toxicity acute; Aquatic environmental toxicity chronic |

How to be compliant with GHS.

Achieving compliance with GHS labeling involves several key steps:

Classification: Chemical manufacturers must classify their products according to the GHS criteria, taking into account their physical, health, and environmental hazards.

Labeling: Once chemicals are classified, appropriate labels must be generated and affixed to containers. GHS labels include standardized elements such as pictograms, signal words, hazard statements, and precautionary statements to convey essential information about the hazards of the substance.

Safety Data Sheets (SDS): Alongside labels, SDSs provide more detailed information about the hazards of chemicals, including their composition, safe handling procedures, and emergency response measures. Employers must ensure that SDSs are readily accessible to employees and that they are trained on how to interpret and use this information.

Training and Education: Employers are responsible for providing training to employees who work with hazardous chemicals, including instruction on how to read and understand GHS labels and SDSs, as well as safe handling practices and emergency procedures.

Periodic Review: GHS labeling requirements may evolve over time, so it’s essential for organizations to stay informed about updates and revisions to ensure ongoing compliance.

There are a variety of options to consider when deciding how you will meet GHS labeling requirements. It is important to determine which method will best meet your business needs while also allowing for process improvements.

Single Color Print-on-Demand

For instances when there is a low mix of label sizes and chemicals to be identified, the use of an existing one-color printer might be sufficient. Label stock would need to be ordered from the supplier with pre-printed red diamonds. Pictograms, signal words, hazard statements, supplier information, and other text would be printed on-site and on-demand. This solution, while cost effective without the investment of an additional printer, may be taxing on space and inventory as large quantities of label stock will need to be kept on the shelves. Additionally, logistical challenges can arise if there are multiple label sizes, each with different quantities of pre-printed diamonds that need to be properly managed and correctly utilized for different applications.

Dual-Color Print-on-Demand

Organizations familiar with thermal transfer print technology might feel most comfortable using it for GHS-compliant labeling as well. A thermal transfer printer with two inline print units that offer simultaneous printing of two colors on one label can meet those needs. Because staff is already familiar with the technology, very little education or training is needed, and implementation time can be short. With the ability to print two colors at once at speeds of up to five inches per second, this print method also offers the potential for increased throughput.

One of the primary reasons thermal transfer printing is a preferred technology is because of the durability of the label stock and the quality of the images. To achieve these results however, it is critical that the label stock and ribbon be carefully matched; working with an experienced solutions supplier will ensure proper label/ribbon kitting to withstand the expected environment. Important when there is a need to print multiple label types and sizes, which also might require printed content changes, thermal transfer print-on-demand provides the flexibility to print labels up to 6” in width.

With a moderate price-point and ribbon-saving feature, the total cost of ownership for a thermal transfer printer solution can be a cost-effective, easily implemented solution for organizations with a need for color and the flexibility to print on demand. With the option to upgrade to a printer-applicator, improved efficiencies and fast return on ROI can be realized for organizations that print high volumes. An added benefit is that a two-color printer can be utilized for other labeling applications that might require minimal color (logos, product info, etc.) All thermal transfer printer providers agree that print heads should be considered a consumable, just like labels and ribbons. Print heads should be regularly cleaned and replaced; with the proper maintenance, they can last up to 3 million lineal inches of printed stock.

Fully Pre-Printed Labels

Only relevant for applications that do not require flexibility for real-time data to be printed on-demand, another option to meet GHS-compliance would be to purchase fully pre-printed labels from your solutions supplier. The benefit is that no process changes will occur internally as a result of GHS, and compliance will be met with minimal impact. The drawback is that this option is limited to a select few organizations, and can pose inventory and space issues when pre-printed label stock must be kept on-hand and used accordingly.

GHS-regulations offer the opportunity to improve upon existing business process and workflows. In working with the optimal solutions supplier, not only will the project end in compliance, but perhaps in increased throughput, reduced costs, and a long-term plan for best practices in overall classification and identification.