Each individual assay plate within your drug discovery lab contains critical data necessary for developing new therapeutics. However, misidentifying or losing track of plates is a frequent challenge that can lead to costly setbacks, compromised data integrity, and delayed research progress. In this article, we’ll explore the common causes of misidentified assay plates in drug discovery labs and provide actionable strategies for properly identifying, tracking, and managing sample and assay data.

Understanding the Challenge

Misidentifying assay plates is a common hurdle in drug discovery. It jeopardizes research integrity, leading to setbacks and delays. Labs that struggle with losing track of specific plates or experiment data should audit their processes to pinpoint unique gaps, common causes include human error, high throughput demands, and imprecise, offline data management. Understanding these challenges aids in implementing effective solutions.

Human Error

Human fallibility can ensue despite stringent protocols, leading to confusion or losing track of assay plates. Such errors may arise from misinterpreting handwritten labels, inaccurately transcribing data, or inadvertently mishandling plates during experimental procedures. Furthermore, the repetitive nature of lab tasks and the pressure to maintain throughput levels can exacerbate the likelihood of human errors occurring.

High-Throughput

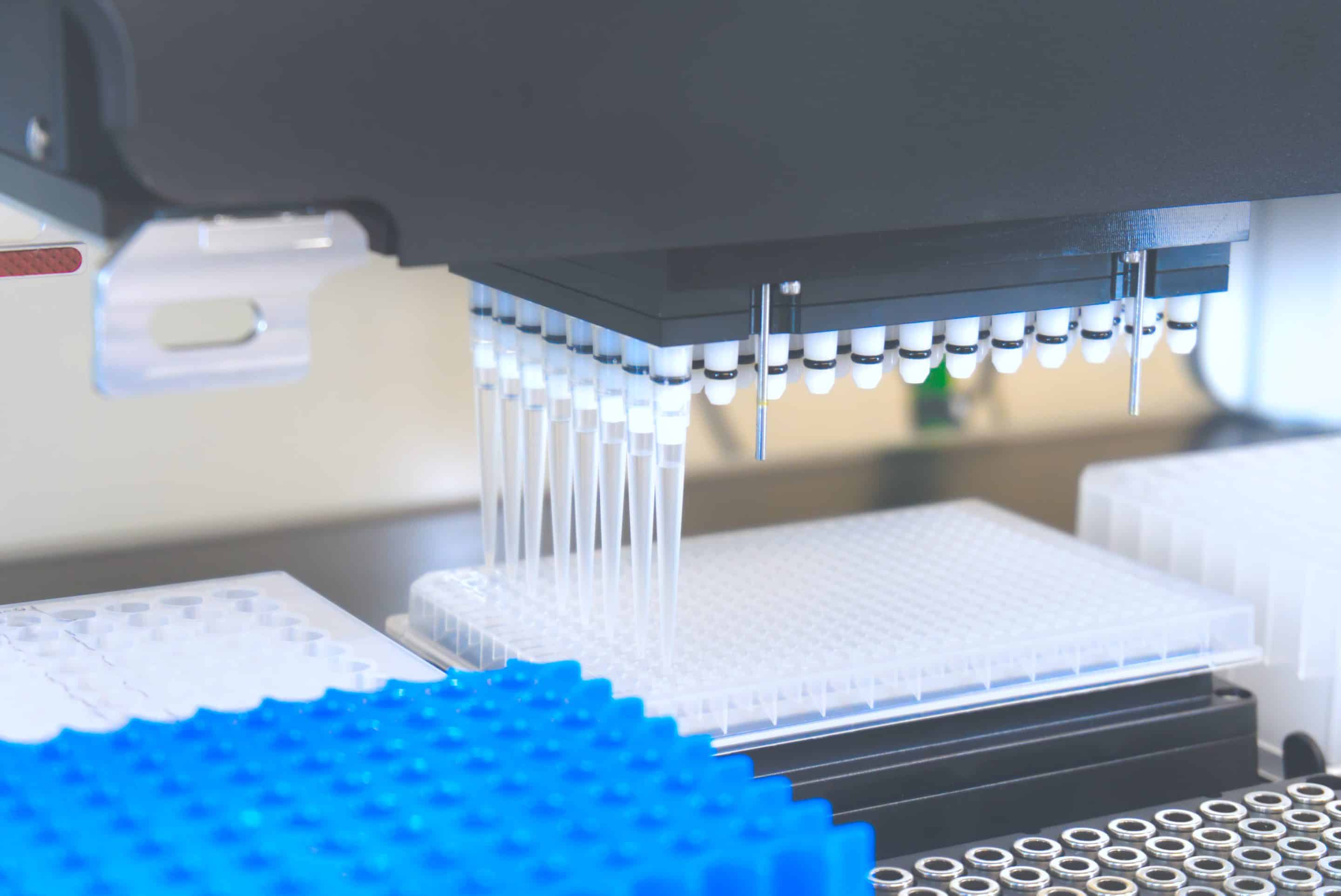

Drug discovery labs often contend with an onslaught of assay plates, heightening the risk of misidentified plates, particularly within high-volume scenarios, including high-throughput screening (HTS) assays. The sheer volume of plates processed in a high-throughput environment as researchers strive to expedite the screening process to identify promising drug candidates increases the complexity of plate tracking and the probability of misidentification.

Imprecise Data

The reliance on handwritten or offline data records introduces additional challenges in accurately identifying and tracking assay plates. Manually recording well contents, experimental details, and other related plate information on pen and paper, or even in a local spreadsheet, limits data accuracy, completeness, and accessibility. Moreover, the lack of standardized formats and protocols for offline data tracking can lead to discrepancies in how information is documented and interpreted.

Best Practices for Assay Plate Identification and Tracking

To mitigate the risk of misidentified assay plates and ensure data integrity, drug discovery labs can implement data-driven strategies and solutions including barcode technology and digital sample management. Here are some comprehensive best practices to help you get started:

Barcode Plate Labels

Uniquely identify individual plates with barcodes, which serve as a digital identifier linking the plate to its corresponding experimental and sample data. Implementing a robust barcode system should be a fundamental practice in drug discovery labs, streamlining identification and tracking processes and securing reliable audit trails. By leveraging barcode technology, labs can minimize errors associated with manual data entry, and facilitate seamless integration with software and instruments.

Digital Well Plate Mapping

Many LIMS interfaces will allow you to digitally map individual wells and provide a comprehensive, interactive overview of the spatial arrangement of wells and associated experimental conditions. By digitally managing plate layouts, researchers can reliably facilitate the precise identification and tracking of well contents and ensure accurate interpretation of assay results.

Multiple Barcodes

Facilitate proper orientation and handling through complex automated workflows by labeling multiple sides of your microplates for redundancy and ease of scanning. This setup allows for consistent identification regardless of the orientation of the microplate – facilitating dynamic routing and allowing automated workflows to run without interruption.

Custom Human Readable Labels

Enhance at-a-glance identification by tailoring your labels to meet your exact needs. Including custom text, symbols, numbers and dates can allow you to accurately represent unique batches and experiments, increase confidence, reduce errors, and maintain well-organized workflows.

Electronic Recordkeeping

Achieve ultimate visibility by embracing electronic laboratory notebooks (ELNs) and laboratory information management systems (LIMS), along with a strong sample management solution for tracking laboratory assets and inventory. Digitally documenting experiment details, plate movements storage locations etc. ensures centralized and retrievable records.

A Closer Look: High-Throughput Screening

Let’s delve into a common scenario within drug discovery: high-throughput screening assays aimed at identifying promising compounds from millions of candidates.

Barcodes and digital tracking systems play a pivotal role in supporting high-throughput screening (HTS) assays, particularly in the context of managing vast amounts of data and samples efficiently. Initially, in the assay design phase, barcodes are utilized to label various components such as cell lines, reagents, and plates, ensuring accurate tracking and identification. As HTS often involves high-density assays with numerous samples and plates, barcoded microplates enable seamless miniaturization, allowing for simultaneous testing of multiple compounds in compact formats like 384- or 1536-well plates. This miniaturization not only conserves resources but also increases throughput. Moreover, barcodes associated with each microplate facilitate easy tracking and identification during assay execution, ensuring that samples are processed accurately and consistently.

Throughout the HTS process, from primary screening to hit confirmation and validation, barcodes and digital tracking systems enhance sample management and data integrity.

Barcodes are assigned to individual compounds within the library, enabling precise tracking of hits and lead compounds identified in primary screens.

During hit confirmation and validation, barcoded samples ensure accurate transfer between plates and assays, minimizing errors and maintaining sample integrity. Digital tracking systems integrate barcode data with assay results, facilitating the analysis of dose-response curves and other parameters critical for hit characterization and lead optimization.

Additionally, in secondary assays aimed at validating hits, barcodes enable efficient tracking of compounds through various experimental conditions and replicate assays, ensuring reproducibility and reliability of results.

In lead optimization, where iterative cycles of compound modification and testing are common, barcodes provide a means of tracking compounds’ performance across different assays and experimental conditions. Barcoded compounds are monitored for potency, selectivity, and other pharmacological parameters, with associated barcode data enabling researchers to trace each compound’s history and performance metrics over time. Furthermore, digital tracking systems integrate barcode data with assay results and chemical structures, facilitating structure-activity relationship (SAR) analysis and informing rational drug design efforts. Overall, the integration of barcodes and digital tracking systems into HTS workflows enhances efficiency, accuracy, and reproducibility, ultimately accelerating the drug discovery process and the identification of novel therapeutic candidates.

Misidentified assay plates pose a significant challenge in drug discovery, but with the right strategies and tools in place, labs can minimize the risk and ensure data integrity throughout the entire research process. By adopting comprehensive best practices including barcode technology, digital plate mapping, electronic recordkeeping, and at-a-glance identification, drug discovery labs can streamline workflows, enhance data reliability, and accelerate the development of new therapeutics.