The Tube Pro is our benchtop tube and vial label automation solution, designed for labs with limited space seeking higher efficiency and accuracy in their labeling strategy. We teamed up with our partners in the automation engineering space to engineer the Tube Pro and bring our customers a solution to their tube and vial labeling concerns for the long term with our service and support.

So let’s dive in.

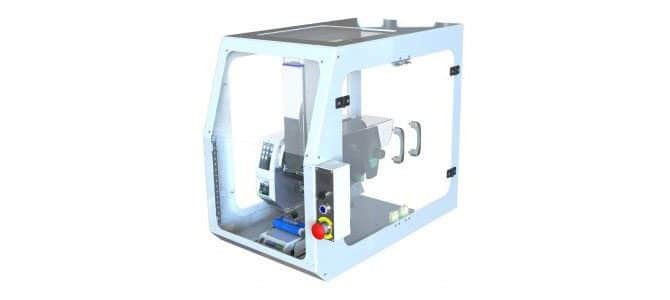

The Tube Pro system breakdown

The Tube Pro system is made up of two parts, the Tube Pro label applicator and the light curtain.

The Tube Pro label applicator provides faster, more accurate and user friendly labeling by allowing the operator to simply place the tube or vial in the nest, where it is held in place. Once triggered, the applicator applies the label and the rollers in the nest flatten and secure it.

Nests are customized to fit specific tubes or vials, ensuring a tight fit and precise label placement.

The printer within the Tube Pro uses thermal transfer print technology since it is the most resistant to common lab exposures. This does limit the ability to print in color, however the applicator can be used with pre-printed labels if color printing is part of your practice.

The light curtain senses the operators hand as it enters and exits the unit, triggering the Tube Pro to apply a label to the tube as the operator removes their hand.

By combining the automated label application of the Tube Pro with the sensory technology of the light curtain, labels can be applied quickly and consistently. This system makes it easy for an operator to set a tube in the nest, grab another, remove the labeled labware and insert another tube without the interruption of pressing any buttons.

Major benefits of the Tube Pro system

Most labs find value in the compact size and precise label placement of the system. Compact enough to fit on a benchtop, the Tube Pro offers increased efficiency and accuracy to facilities where space is a concern and accommodates volume levels consistent with small to medium sized labs. Larger labs can also benefit from a Tube Pro system for smaller batch projects, or by utilizing multiple machines to accommodate various tube and vial shapes and sizes.

The Tube Pro is also able to integrate with your LIMS system to accommodate custom time sensitive variable data and simplifying the implementation process.

The increased accuracy of placement provided by the Tube Pro automated labeling system also allows for increased efficiency down the line, especially when automated processes are integrated into your workflow. With the labels placed consistently, higher read rates can be achieved reducing bottlenecks down the road.

Like many other automated tools, the Tube Pro was designed with leaner processes in mind—increased efficiency and reduced opportunity for errors leads to lowered waste in the forms of physical product, time, space and budget.

With that, here are a few additional notable features of the Tube Pro:

- The Tube Pro system can print both linear and 2D barcodes, or apply pre-printed labels.

- Operators can easily change nests without tools for minimal interruption when switching to a new tube size.

Keep in mind that the nests used to hold tubes and vials in place during labeling are designed to be used with a single tube size—meaning you must purchase multiple custom nests if labeling multiple tube sizes, and change your nest when changing tube sizes.

How much does the Tube Pro cost?

Any piece of automated equipment is an investment—however, if you feel like automation aligns with your bottom line, its worth considering.

The main drivers of cost when it comes to tube and vial automation are:

- operator involvement

- throughput volumes

- the variety of tube and vial sizes the equipment is expected to accommodate.

As a low to medium throughput, benchtop solution, The Tube Pro system begins at $35,000+ —with price adjustments depending on customization options, the number of nests you require and labeling terms.

When calculating if this decision is right for you consider the time and resources your lab currently dedicates to identification and tracking. Do you need to free up your employees to focus on research goals? Do you need to reduce time spent on waste and stoppages caused by inaccurate scans or potentially mislabeled samples? Are you confident in the integrity of your data and audit trails?

Will my labels work with the Tube Pro?

There are a number of moving pieces associated with implementing a new tube and vial labeling strategy. One of the most critical factors is ensuring your labels are compatible with the new equipment.

The construction of your label needs to be engineered to move smoothly through the applicator without issue—otherwise you might face stoppages. For example unfit adhesives could ooze and gum up the equipment, and labels that are too thin may not peel from the liner properly.

Issues like these can be avoided by sourcing your equipment and labels from a single supplier like Computype. When you source all equipment from one place, your supplier will be able to suggest combinations that are known to work, spot potential issues before they occur and they might even be willing to test out solutions that are yet to be confirmed if you’re looking for something specific.

Working with a single supplier not only allows for optimization of the system itself, but provides closed-loop service and support.

Incompatibility between labels and hardware is the most common source of issues when it comes to automatic label application, so it is imperative your label supplier knows how you intend to use your labels and qualifies them accordingly.

What else can my implementation partner help with?

Additionally, there will be some necessary adjustments in terms of logistics. From making the proper arrangements to the organization and layout of your facility, to connecting your LIMS database with the systems HMI.

All of these considerations can be handled seamlessly with the help of a strategic partner. Integrated labeling automation systems should be designed and commissioned to meet your needs today—and in the future. The right partner will ensure proper understanding of your goals to provide labels and systems that will hold up to unexpected growth, expansion, and procedural changes.

Don’t spend your time managing a complex labeling system without the proper support, choose a partner that can lay a good foundation for your anticipated growth.

To sum it all up, the Tube Pro is a great benchtop tube and vial labeling solution for labs processing low to medium volumes of samples with limited real estate. As a Computype product, you benefit from more than the equipment alone, but through our services as a solutions partner—ensuring your Tube Pro system and all components are optimized to provide efficiency and accuracy now and in the future.