1. Labeling plates by hand

With low-volume applications, labeling microwell plates by hand is always an option. To accomplish this, you need pre-printed label stock, a printer, label stock materials, and a workforce. In addition to low-volume applications, this labeling method is also suitable for inconsistent lab operations and does not require complete precision of placement or guaranteed consistency. To simplify things, if your barcode labeling process does not require variable information, labels can be pre-printed by your supplier and sent to you ready for immediate application.

If your lab is starting up, your volumes may be inconsistent, and you are working to control costs; in that case, manual labeling of microwell plates could be the best solution for you. With this option, you are minimizing costs and keeping processes simple.

Additionally, the information needed on your labels includes variable data such as date or lot codes. In that case, manual labeling may be the most efficient way for your lab to label microwell plates. In short, with manual labeling of microwell plates, flexibility is optimized; you can manually swap out label stock, utilize the same printer for other needs, and determine your batch size based on current project needs.

While manual labeling is commonly utilized in many healthcare functions, significant drawbacks exist. Obviously, manual labeling involves a human workforce; with this comes inevitable inconsistencies and errors. Microwell plates are often home to small samples, and the manual labeling process could compromise the integrity of your samples and their respective information.

Additionally, if your lab decides to label by hand, realize employees are responsible for keeping inventory of all necessary materials like labels and ribbons and maintaining a printer, which can be more costly if errors or inconsistencies occur. Labeling by hand can also pose other challenges. Standard Operating Procedure often requires employees to wear gloves, which labels are prone to sticking to and can make for inefficient labeling practices.

For some labs, the option to hand label microwell plates might not even be available because not all labels stand up to harsh chemicals. In these cases, direct marking must be done via an in-house operation or an outsourcing program. It is essential to discuss the expectations of your barcodes with your supplier before you settle on any labeling method.

2. Automated microplate labelers

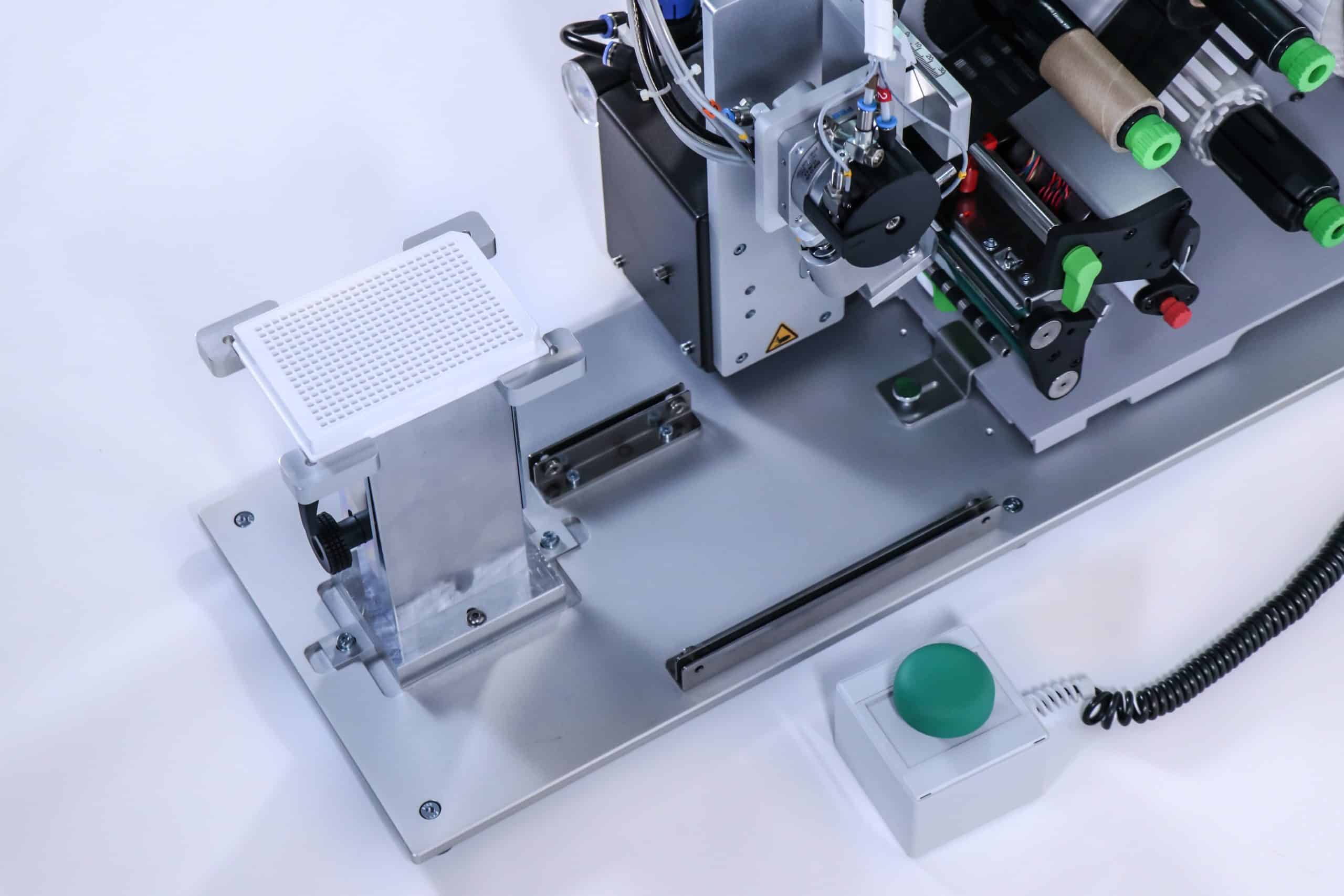

Another option for barcoding your microwell plates is via label automation. Label automation has become a more prevalent means of barcoding as it increases efficiencies in the lab. The two most effective ways to automatically apply labels are the cab SQUIX/S3200 plate labeling solution, or the Eclipse plate labeler series.

This product suite offers efficiency and flexibility as it can be utilized as a standalone unit or easily integrated into a workflow system. The Computype Plate Labeler has a motorized rotational axis, allowing it to automatically label up to four sides of the plate in a matter of seconds based on the selection made by the operator through the interface panel.

Automation is essential as your process utilizes other automatic workflows; precise label placement is crucial for later when the barcodes are automatically scanned for accurate identification. If barcodes are precisely and correctly placed, the integrity of the samples can be maintained, creating the potential for backlogs. Automated microwell plate labeling is the most beneficial option for a few cases:

- High-volume applications: With high-volume applications, automation can expedite the process and enable a higher throughput rate. This increases efficiency, integrating label application with your existing process.

- Larger automated processes: As mentioned above, automation is becoming more widely used in the healthcare industry. Suppose you are already utilizing automatic processes or looking to move towards automation. Many of these systems can be easily integrated, further promoting this shift and ensuring consistent scan rates.

- Label placement consistency is critical: This is common in healthcare when human samples and specimens are held in microwell plates. Conserving the integrity of a sample is always the priority, and label placement accuracy and consistency further promote that initiative.

As with any method of labeling, label automation does have its drawbacks. Typically, this shift in process will include capital expenditure, although ROI can be easily justified. Additionally, although less space for manual labor is needed with the implementation of automation, you will need to plan for the real estate required to house an automatic applicator within your lab. This is not necessarily a drawback. However, it needs to be prepared for.

3. Outsourcing pre-barcoded microplates

Specific label and labware suppliers have outsourcing programs where they will procure and label your microwell plates to accommodate your barcode and labeling specifications. This solution enables you to be completely hands-off regarding labeling and leaves you to focus on more valuable laboratory processes.

Here at Computype, we offer Labware Prep™ Services, a program in which we procure labware, determine the best method for identification based on your unique specifications, mark the plate, and then send them your way (or send them directly to your customer!). This is the ultimate option for time and labor savings. The Labware Prep™ Services program removes the need to store labels, labeling, and labware supplies.

As with all options, there are drawbacks. Although an outsourcing program provides flexibility, time, space, and manual labor savings, the option of outsourcing takes direct control over labeling away from your lab as you are not in-house to oversee the process. This is why working with a label manufacturer you trust and will work with to ensure they match your specifications is very important.

Automated Microwell Plate Labeling and Pre-Barcoding in the Laboratory

Comptype’s automated labeling and pre-barcoding technology is used on microwell plates in laboratories around the world, improving the accuracy of sample tracking and saving time and labor in a wide range of scientific laboratory settings, including:

- Biopharma & Biotech

Improving accuracy in drug development and delivery, diagnostic testing, biomanufacturing processes, sequencing pipelines, bioinformatics, synthetic biology and advances in precision medicine. - Analytical & Quality Testing

Enhancing processes in the development of new instrumentation and methods, sample preparation techniques, result validation, quality assurance and control, sensitive detection limits, informatics and sustainability applications. - Transfusion Medicine

Optimizing efficacy in the fields of blood group serology, RBC antigen stability, blood component manufacturing, synthetic blood substitutes, immunohaematology diagnostics and transfusion analytics. - Clinical & Diagnostics

Optimizing workflows in the development of diagnostic testing, clinical technologies, bioinformatics pipelines, companion diagnostics, and telehealth solutions. - Biobanks

Refining processes in biospecimen collection, sample processing, informatics, storage, monitoring, distribution and sharing. - Compound Management

Improving efficiency in compound acquisition and registration, quality control, plating, storage, distribution and inventory management.

The enhanced identification and tracking capabilities offered by automated labeling and pre-barcoding of micro well plates contributes to the overall efficiency, accuracy, and reliability of experimental processes in a wide range of fields, including:

As you can see, various options exist for labeling your microwell plates, whatever your discipline or field of study. Labeling by hand, integrating label automation into your lab, or outsourcing your labeling are all viable options and could be beneficial options for your lab. Computype has the resources to accommodate these options and can help you determine the best option to suit your goals and processes.